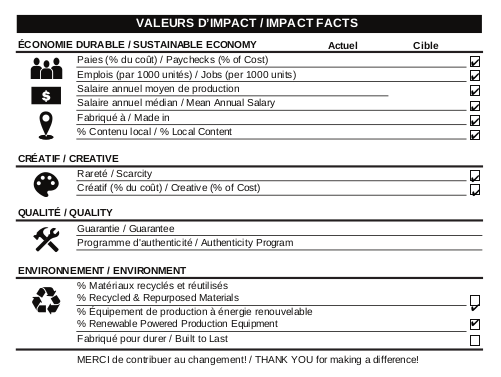

Paychecks to People: Understanding the Impact of Direct Labour, Creativity, and Selling Costs

At FABICI, we feel strongly that driving labour out of the costs of products will have a harmful long term effect on the sustainability of our global economic systems. As a result, we choose to highlight how much of the purchase price of our products goes back into the hands of those involved in producing it.

Paychecks to people?

Paychecks to people is a term we use to describe the total amount of money we pay to the employees building, selling and supporting the production of our products. It includes salaries, commissions, fringe benefits, and any other compensation related to labour. The formula is as follows:

- Paychecks to people = Direct Labour + Creative + 83% of selling costs (0.83*0.58*SGA) + 69% of General and Administration (0.69*0.42*SGA) + GiG-E Contributions + Projected PSP (profit sharing plan – currently 0)

Average and Mean production salaries

Coming directly out of our ERP, where labour rates and fringe benefit calculations are stored.

Jobs / 1000 parts

An estimate of how many full time employees we would need to produce 1000 units of the product. It is calculated by: paychecks to people / average production salary. (We recognize that this might be inflated, as many jobs are not directly proportional to our production volume. )

Direct Labour

Direct labour refers to the time and effort employees spend on tasks that directly contribute to the production of goods or services. This includes CNC machining, assembly line work, finishing, etc.

Selling Costs

Selling costs refer to the expenses a company incurs to promote and sell its products or services. These can include advertising, travel expenses for salespeople, and commissions for sales staff. Most importantly, there are payroll expenses for the sales and customer service teams.

Since FABICI is only just starting up its operations, we modelled the payroll cost component based on our parent company. Of all Selling Costs, 83% go to payroll.

General and Administrative Expenses

In addition to selling costs, there are also general and administrative expenses to consider. These are the expenses a company incurs to support its operations, but which don’t directly contribute to revenue generation. Examples include rent, utilities, legal fees, and payroll expenses for administrative staff.

Based on historical operations of our parent company, we attribute 69% of general and administrative expenses to payroll.

Local Content and Renewable Production Equipment

Finally, there are two other elements to consider in our Impact Facts: local content and renewable production equipment. Local content refers to the percentage of materials used in production that are sourced from within the country of operation. Renewable production equipment refers to the percentage of labour costs that come from renewable-powered equipment.

Local content

- 100% of materials when COO (Country Of Origin) and COS (Country Of Supply) are both Canada

- 30% of materials when COO is NOT Canada, but COS is Canada (EG: buying a Chinese speaker driver from a local distributor here in Montreal)

Renewable production equipment:

Percentage of labour cost that is from renewable powered equipment. Each piece of equipment used during our production is assigned a factor. For example:

Montreal’s plant

-

- The general plant labour is assigned 50% because we use a mix of natural gas and hydroelectricity to heat and power the facility

- CNC Machines: are assigned 100% renewable because they run on 100% Hydro-Electric power

- Compression Moulding Presses: assigned 0% because they are heated with natural gas.

In the future, we will improve our calculations to better incorporate the proper carbon footprint and leverage great sources of information such as the electricity CO2 map https://electricitymap.org/

By increasing local content and using renewable production equipment, we obviously hope we can reduce our overall environmental impact. Local sourcing as many of our materials as possible can also have a great impact on the energy used in transportation costs.

Leave a Reply